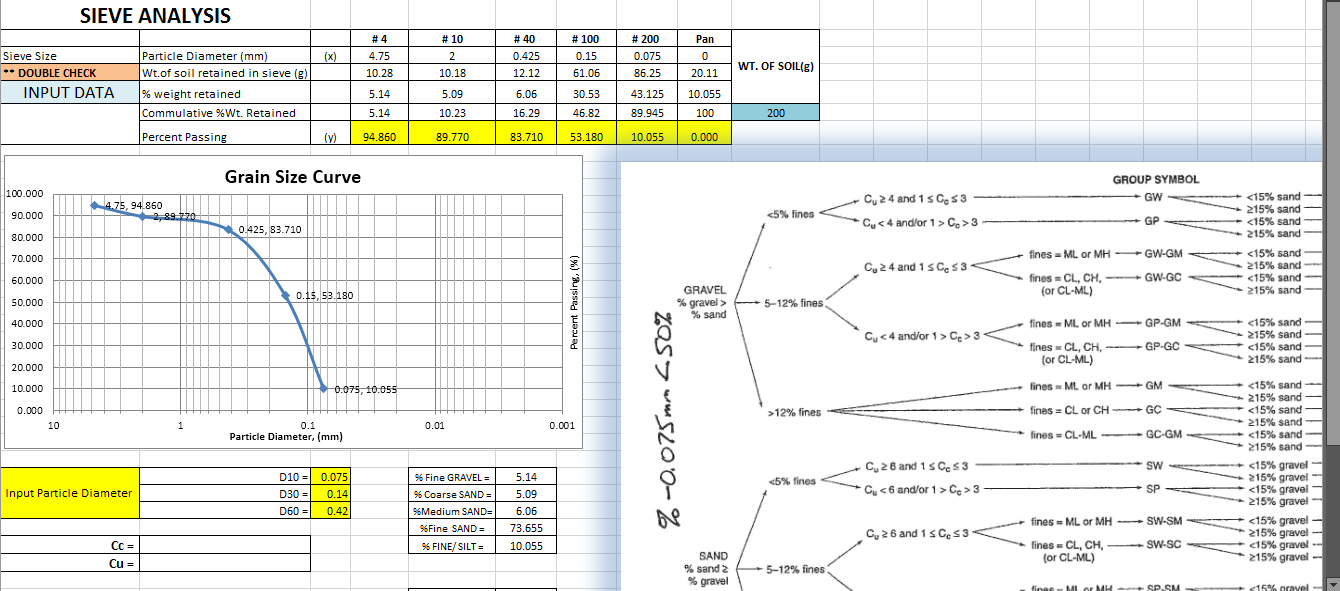

A sieve analysis (or gradation test) is a practice or procedure used in civil engineering and chemical engineering to assess the particle size distribution (also called gradation) of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a fraction of the whole mass.

The size distribution is often of critical importance to the way the material performs in use. A sieve analysis can be performed on any type of non-organic or organic granular materials including sands, crushed rock, clays, granite, feldspars, coal, soil, a wide range of manufactured powders, grain and seeds, down to a minimum size depending on the exact method. Being such a simple technique of particle sizing, it is probably the most common

METHODS OF SIEVE SIZE ANALYSIS

Determination of article size is more important in Civil Engineering, as the particle size determines the effectiveness of final product. The characters of particle such as bulk density, physical stability, permeability and many more are decided by its size. To determine the size distribution of particles, the sieve analysis test procedure is an effective method that prevailed from the past. In sieve analysis, the particle size distribution is defined using the mass or volume. Sieve analysis is laboratory test procedure in which particles will move vertically or horizontally through sieve mesh. Depending on the needs and particle material different sieving methods are available for the application. They are manual sieving method, mechanical sieving method, dry sieving method and wet sieving method.

Manual sieving method is carried out in places where there is no electricity and mainly used in, onsite differentiation among large and small particles. Mechanical sieving method is used in laboratories to assure the quality and this is the widely using method in present days. In mechanical sieving the method can be classified into two further groups depending on their sieving movement as horizontal movement sieving method and vertical movement sieving method. The vertical movement sieving method is also known as throw-action sieving and vibratory sieving methods. Dry sieving method is considered mostly and here the testing particles (specimen) are in dry state. Wet sieving method is considered when the particle that is going to be used is already exists as wet or suspension. Here, in the sieve shaker machine a nozzle will be provided to water the upper most sample material. But need some extra about the water concentration during this wet sieving experiment.

Very helpful. Please send me.

Dear … It’s simple…

Only 2 steps

1- click the link in description of post Of Facebook.

2- Press RED download button…

That’s it

If you still face any issue please let me know