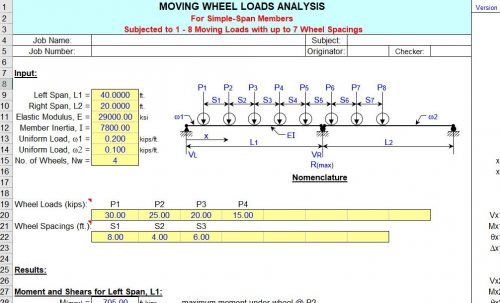

“MOVLOADS” Program

| Program Description: |

| “MOVLOADS” is a spreadsheet program written in MS-Excel for the purpose of analysis of simple-span members |

| subjected to from one (1) up to eight (8) moving wheel loads with up to seven (7) wheel spacings. Specifically, |

| the maximum moment and location from the left end of the member and wheel postioning, the maximum end |

| shears, the maximum deflection, and the maximum center support reaction for two (2) adjacent simple-span |

| members are calculated. |

| This program is a workbook consisting of two (2) worksheets, described as follows: |

| Worksheet Name |

| Doc |

| Moving Loads |

| Program Assumptions and Limitations: |

| 1. The following references were used in the development of this program (see below): |

| a. “Modern Formulas for Statics and Dynamics, A Stress-and-Strain Approach” |

| by Walter D. Pilkey and Pin Yu Chang, McGraw-Hill Book Company (1978), pages 11 to 21. |

| b. AISC 9th Edition Allowable Stress (ASD) Manual (1989), pages 2-298 and 2-310. |

| 2. This program uses the three (3) following assumptions as a basis for analysis: |

| a. Beams must be of constant cross section (E and I are constant for entire span length). |

| b. Deflections must not significantly alter the geometry of the problem. |

| c. Stress must remain within the “elastic” region. |

| 3. To determine the value of the maximum moment and location from the left end of the left span for either only one |

| (1) or two (2) wheel loads, those values are calculated directly by formulas. |

| 4. To determine the value of the maximum moment and location from the left end of the left span for three (3) up to |

| eight (8) wheel loads, the group of wheel loads is positioned with wheel load P1 situated directly over the left |

| support. Then the group is moved to the right in 1/200*span increments, and the left and right reactions as well |

| as the moments under each of the wheel loads are calculated. In moving the group of wheel loads incrementally |

| from left to right, any wheels that would drop off of the span are done so. Then this entire procedure is mirrored |

| for the opposite direction, from right to left. |

| 5. To determine the value of the maximum reaction at the center support of 2 adjacent simple spans, the group of |

| wheels is positioned with the right most wheel load situated directly over the center support. Then the group is |

| moved to the right, one wheel position at a time, until the left most wheel load, P1, is positioned directly over the |

| center support. In moving the group of wheel loads one wheel position at a time from left to right, any wheels at |

| either end that would drop off of the span(s) are done so. |

| 6. The calculated value for the maximum deflection is determined from dividing the beam into fifty (50) equal |

| segments with fifty-one (51) points, and including all of the point load locations as well. (Note: the actual point of |

| maximum deflection is where the slope = 0.) |

| 7. The user is given the ability to input two (2) specific locations from the left end of the beam to calculate the |

| shear, moment, slope, and deflection. |

| 8. This program contains “comment boxes” which contain a wide variety of information including explanations of |

| input or output items, equations used, data tables, etc. (Note: presence of a “comment box” is denoted by a |

| “red triangle” in the upper right-hand corner of a cell. Merely move the mouse pointer to the desired cell to view |

| the contents of that particular “comment box”.) |